Think different.

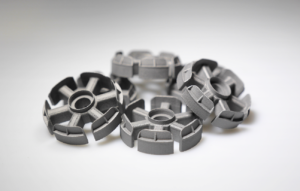

With ‘THINK DIFFERENT’ Raytech illustrates that components can be created in several ways. It is true that every production technique has advantages and shortcomings. That is why we are always looking for the most efficient, economical and most intelligent way to manufacture a particular part.

CNC milling? Additive Manufacturing? Sheet Metal?

As a supplier, Raytech is responsible for the production of parts using subtractive and additive production techniques. It goes without saying that every production technology requires specific knowledge in the field of design and programming. Logically, CNC Milling requires a completely different way of thinking than, for example, 3D printing or sheet metal working.