Laser cutting: prototypes and serial production

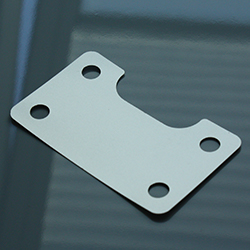

Large series

Specially equipped laser machines (CO2-fiber lasers) are used to produce large series. These machines can achieve ultra high cutting speeds without getting overheated.

Things to consider when laser cutting large series:

- Optimised CNC program (to achieve highest possible cutting speed)

- Multiple cutting heads

- Bulk purchase of raw materials + optimal nesting

- Automatic cleaning (if required, automatic ultrasonic cleaning is possible)

- Automatic camera control (if 100% controlled parts are required, automatic video camera controles can be integrated)

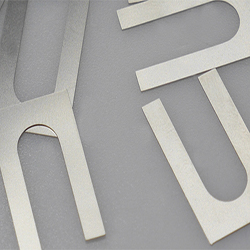

Prototypes and small series

Laser cutting is well suited for creating prototypes and proof-of-concepts. Raytech has several specially equipped laser machines for cutting prototypes and small series. These machines are quickly adjustable and programmable. As a result, prototypes and small series can be delivered quickly.

Besides production services, Raytech also has the possibility to assist companies with the development of components. More information about engineering and product development can be found on the following page: engineering & product development