Product development

Together with the customer, Raytech contributes as a subcontractor into the development of new components. By active involvment in the early stages of the product development cycle, parts & components can be designed tailored to the appropriate production technology.

After designing, prototypes can quickly be obtained by using machines specially equipped for this purpose. Furthermore, Raytech has the possibility to manufacture large series in an economical way. Focus on automation and fine-tuned processes.

“When innovation meets technology”

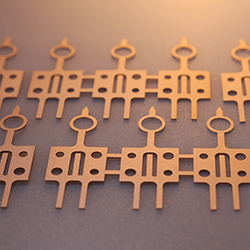

Tailored production processes – mass production

In order to produce large series, a combination of high production-rate machines and extensive process-automation is desirable.

Optimized cutting & CNC-programs, visual camera inspecition during production and robotisation are implemented to economically offer large series.

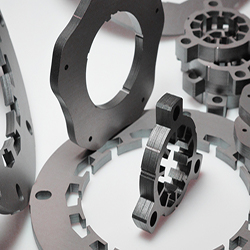

Complex applications

For complex applications which require a specific, niche production process, Raytech likes to search & develop a suitable solution (machine or process).

Raytech already developed several dedicated machines for long term projects, mostly by combining various production technologies. A few examples are: laser-milling set-up, laser-etch process – dual head tube laser cutting machine -… each time to manufacture complex parts at the request of the customer.

Design & prototypes

Raytech supports companies with 2D, 2,5D and 3D designing

2D: (Micro) laser cutting

2,5D: Tube laser cutting & Laser welding

3D: 3D Metal printing

3D metal printing / Additive Manufacturing

is an innovative production technology that lends itself perfectly to produce prototypes or small series. By using 3D printing, proof-of-concept models can be delivered within a few days.

Laser cutting

Just like 3D printing, laser cutting can be a fast way to obtain representative prototypes. For this purpose, Raytech has dedicated laser equipment specially designed for small series, resulting in short delivery times.