What makes us unique?

- High precision & quality

- From prototypes to large quantities

- Co-developing

- In-house machine building

- 35+ years of experience

- Short delivery time

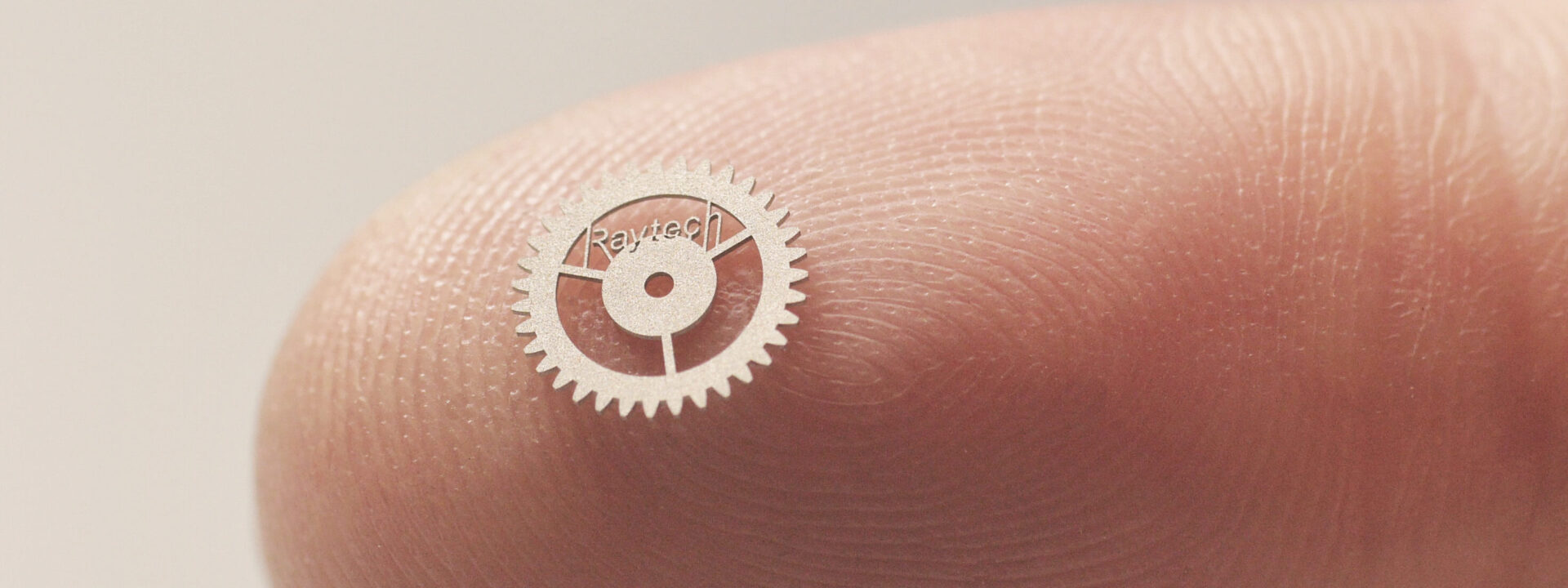

As one of the first Belgian suppliers in (Micro) laser cutting and more recently in 3D printing, Raytech is a pioneer in the production of small & complex parts.

Thanks to in-house machine construction, unprecedented acceleration speeds can be achieved, which allows Raytech to distinguish itself within the industry. Thicknesses up to 0.005mm can be lasered with a tolerance of 10µm. Thanks to these advanced techniques, Raytech is the suitable supplier for prototypes to larger quantities.

We act as a co-engineer to find a solution for the most diverse projects, guaranteeing the highest accuracy and quality. Furthermore, for larger and frequent orders there is the possibility to develop an in-house custom-made machine specifically for your product!

Projects in the spotlight

Large quantity laser cutting

Our Ingenuity and in-house engineering made it possible to choose laser cutting for medium to large quantity orders while having similar or even lower costs than stamping, without some of the drawbacks.

Titanium glasses frames ~ Hoet Eyewear

Shims - Spacers - Washers

Home