Large quantity laser cutting

Competing with stamping

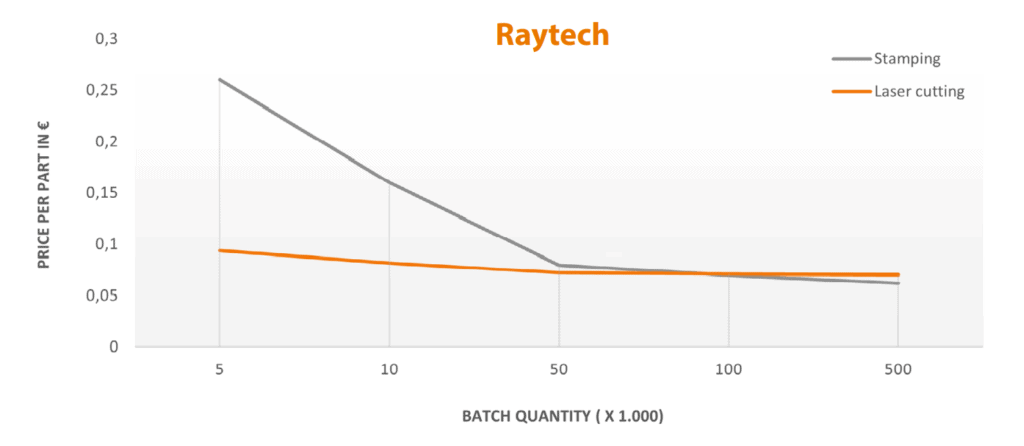

In the metal processing industry it’s a common understanding that stamping is the appropriate way to produce large quantities because of its cost efficiency over large quantity laser cutting.

However, thanks to Raytech’s state of the art machine building, we can leave this old notion behind and provide competitive laser cutting without compromising on quality. Because of our improved technology, we can push down the price point to just this:

Large quantity laser cutting at a comparable or even lower cost than stamping, without some of the drawbacks associated with stamping, has been made possible by our ingenuity and in-house engineering.

The fact that we can provide this kind of high-speed laser cutting, which does not require any upfront tooling, makes it the perfect option to fill in for stamping’s long lead times.

Possible projects are (but not limited to):

- Plastic and thin metal foils

- Shims

- Flat springs

- Fuel cell plates

- Stator/rotor

- …

- Tube cutting

- Gears

- Wire, mesh and filter cloth

- Pre-series for stamping

- …

Precision laser cut spring parts

in-house developed high acceleration laser machine

Standard laser machines are slow to accelerate after a corner, hole or complex contour has been cut. This slow acceleration significantly extends cutting times and valuable production time is wasted.

By using laser equipment that is able to perform fast accelerations, it’s possible to laser cut small components with complex shapes in a fast, efficient and price competitive way.

Raytech built a micro laser machine to achieve high accelerations. This flat bed laser machine is able to cut thin metal parts much faster than standard laser machines on the market, while maintaining high precision.

Depending on material thickness, a tolerance of 20µm is possible. Through further optimization an accuracy of 10µm can be achievable (very limited material thickness).

Ways to improve precision:

- Fine-tuning NC Code

- Optimized nesting, laser width compensations and cutting sequence

- Fixation

- Clamping with base plates

Furthermore, for larger and frequent orders there is the possibility to develop an in-house custom-made machine specifically for your product!

Cutting speed vs acceleration

Despite the fact that cutting speed and acceleration are both important parameters in laser cutting, they are slightly different from each other.

High cutting speeds can only be achieved when cutting larger parts, and in particular on straight sections (a car can easily reach a high speed while driving on a highway compared to a car in the middle of a city center). This means that during the laser cutting of small components, an ultra high cutting speed can not be reached.

However, to be able to laser cut small components ultra fast, acceleration parameters are used. This explains why acceleration is extremely important for fast laser cutting of small and high detailed components.

Home » Large quantity laser cutting